Description

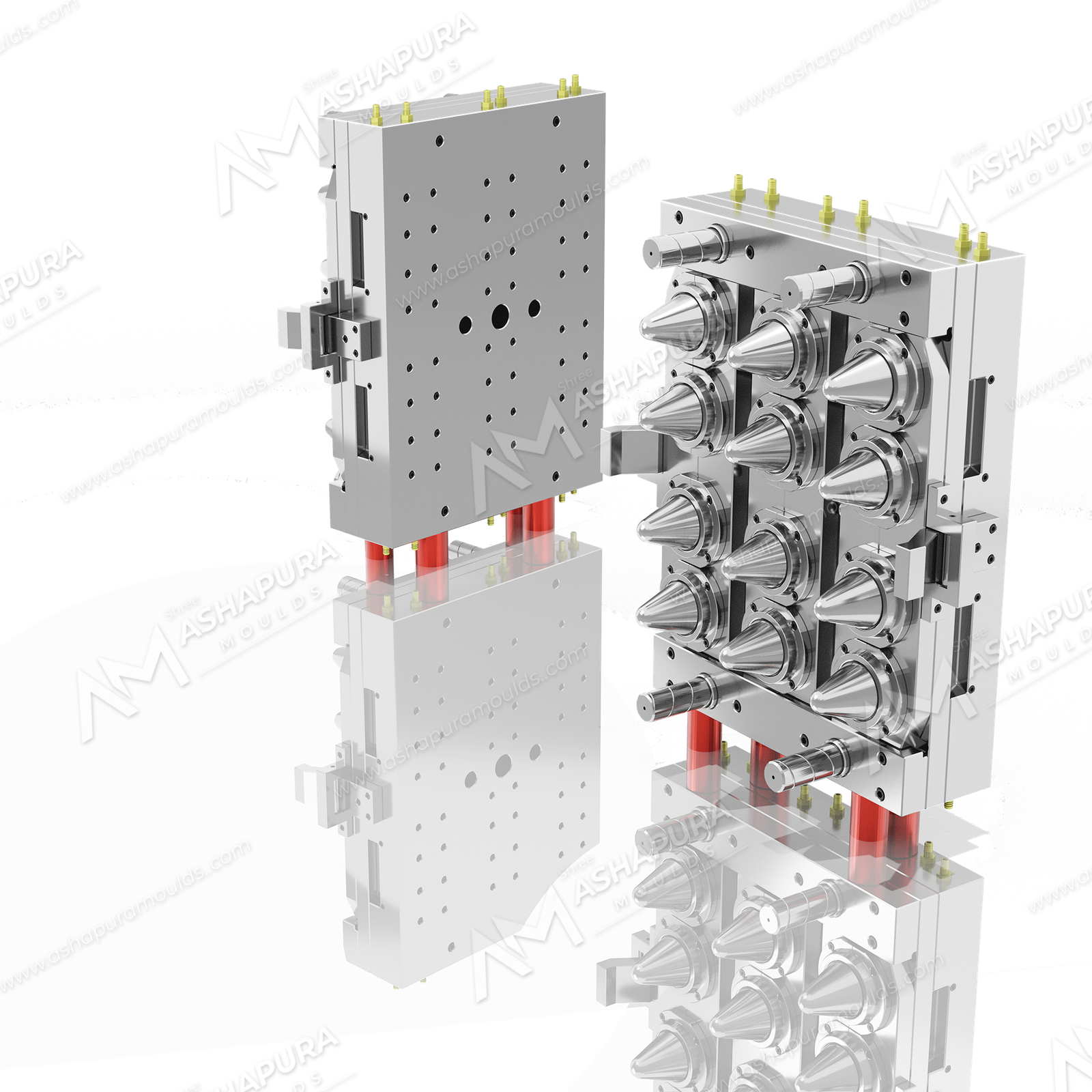

PET Jar Preform Mould: Unleashing Precision and Excellence in Injection Moulding

Welcome to Shree Ashapura Moulds, a trusted name in PET preform mould manufacturing. With our state-of-the-art facilities based in Ahmedabad, we are renowned for delivering high-quality moulds for PET jar preforms. Our advanced moulds, designed using cutting-edge technology and expertise, meet the stringent requirements of the industry, ensuring precision, efficiency, and reliability. If you are looking for the best preform mould in India, look no further than Shree Ashapura Moulds, the preferred choice for leading brands worldwide.

Salient Features of Our PET Jar Preform Moulds

Application of Internationally Advanced Two-Step Dual Taper Locating Technology:

Our PET jar preform moulds utilize the latest two-step dual taper locating technology, ensuring optimal alignment and precise moulding.

This advanced technology, along with our expertise, allows us to deliver consistent quality and exceptional performance.

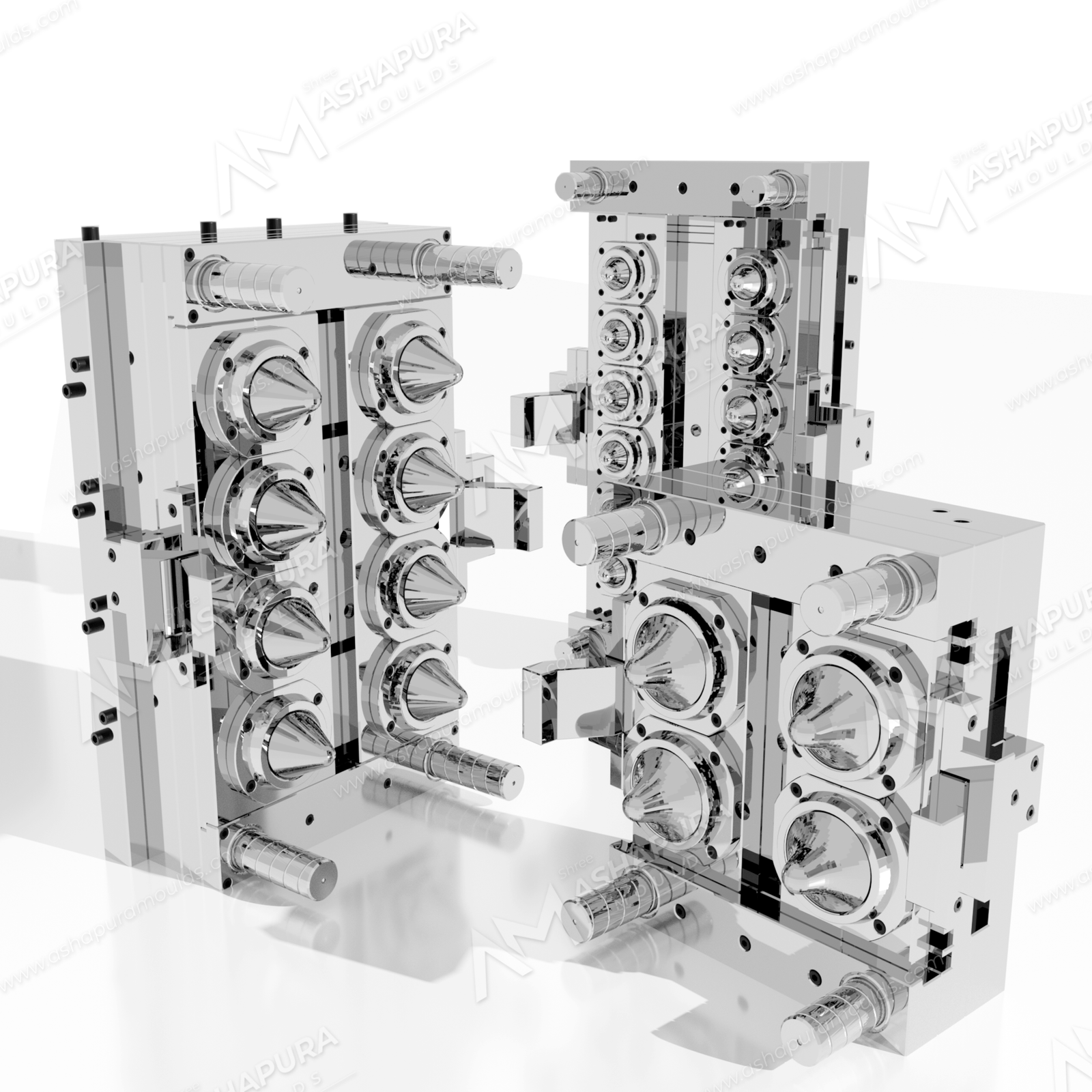

Independent Self-Locking of Each Cavity:

Each cavity of our PET jar preform moulds features independent self-locking mechanisms, providing enhanced stability and control during the moulding process.

This feature, coupled with our meticulous craftsmanship, ensures the production of flawless PET jar preforms.

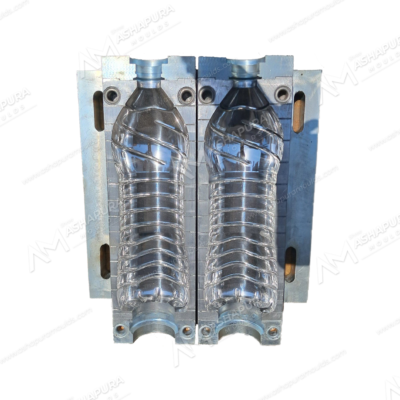

Machining Tolerances as Low as 0.005 mm (5 Microns):

We employ advanced machinery and techniques to achieve machining tolerances as low as 0.005 mm (5 microns) in our PET jar preform moulds.

This level of precision guarantees accurate dimensions, smooth operation, and reliable performance.

Balanced Arrangement of Cooling Channels and Turbulence:

Our PET jar preform moulds are designed with a balanced arrangement of cooling channels and turbulence, enabling efficient cooling and optimal heat transfer.

This feature, combined with our expertise in mould design, results in reduced cycle times and improved productivity.

Modular Design for Ease of Replacement:

We understand the importance of minimizing downtime in production. Hence, our PET jar preform moulds feature a modular design, allowing for easy and quick replacement of components.

This design approach, combined with our commitment to delivering high-quality products, ensures uninterrupted production and reduces maintenance costs.

Variation in Preform Wall Thickness of ±0.10mm:

Our PET jar preform moulds offer precise control over the wall thickness of preforms, with a variation of ±0.10mm.

This level of accuracy ensures uniformity in the final product, providing consistent performance and meeting industry standards.

Valve Gate Hot Runner System:

We integrate a valve gate hot runner system into our PET jar preform moulds, ensuring precise control over the injection process.

This system, in collaboration with industry-leading suppliers like Husky and Acme, minimizes material waste, reduces cycle times, and delivers clean, high-quality preforms.

Conclusion

When it comes to PET jar preform moulds, Shree Ashapura Moulds stands out as a trusted partner for manufacturers in India and beyond. Our commitment to delivering the best preform moulds, along with our expertise in injection moulding and collaboration with renowned suppliers like Husky and Acme, ensures that our customers receive products of exceptional quality and performance. Contact us today to experience the precision, efficiency, and reliability of our PET jar preform moulds and take your injection moulding processes to new heights.